HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | Dent damage in subsea environment |

| DETAILS | 16” OD – design temp. 65°C – design pressure 92.5 barg |

| LOCATION | Su Tu Vang, VIET-NAM |

| 3X PRODUCT | REINFORCEKiT 4D Subsea (R4D-S) |

OVERVIEW

The objective of the repair performed by 3X ENGINEERING (3X) and its local distributor PETROENERTECH was to reinforce a damaged subsea pipe section over 1 meter length, due to dent defect situated at 55-meter depth (3.3 % dented depth).

SCOPE OF WORK

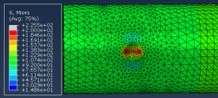

Finite Elements Analysis (FEA) simulation has been performed by 3X to determine the number of layers necessary to perform the reinforcement 30 composite layers of REINFORCEKiT 4D SUBSEA (R4D-S) product have to be implemented.

Several preliminary actions have been performed underwater (identification of the defected area, removal of concrete and existing concrete …) prior to prepare the surface with sandblasting device. This step is absolutely necessary to get a good surface roughness (60-micron surface profile). To blast the whole surface to be repaired, 5 dives were conducted.

3X wrapping reinforcement has been performed following several stages :

1/ Primer (P3X32) application on the whole defect to provide a good adhesion of the filler.

2/ A rigid composite plate coated with F3XSS filler to rebuild the pipe shape has been positioned over the dent and strongly fixed with ratchet belts during few hours.

3/ Second P3X32 application performed on the whole pipe surface to be repaired before wrapping.

4/ Kevlar® tape pre-impregnated with R3X1050-S resin (using special 3X device called BOBIPREG) wrapped around the pipe. Thirty layers were necessary to cover the dent (i.e. 15 passes of 50% overlap).

To make sure the repair was conform to requirements, various measurements have been taken (total length of the repair, repair circumference and hardness measurements).

RESULTS

The 16” sea line was efficiently completed within 2 days. The total length of the repair was 1.05m. This project was a big challenge because of the 55-meter depth which is a very restrictive environment and needs diving limited times. Thanks to our experience in subsea repairs added to the great collaboration between PETROENERTHECH, client representatives and PVMTC divers, this subsea repair was one more success.