REINFORCEKiT® 4D

REINFORCEKiT® 4D (R4D) is a wet lay-up system, wrapped helicoidally around the pipe in order to bring the mechanical resistance to the damaged pipe section. The number of layers, determined by calculation, is linked not only to the pipe pressure, temperature, diameter and thickness but also to the pit depth and length, the steel grade and the pipe location. The repair design and material requirements are provided by 3X software REA after information compilation according to ASME B31G, ISO 24.817 and ASME PCC-2 codes and standards.

REINFORCEKiT® 4D is recommended to repair and reinforce pipelines operating at temperature between -50°C (-58°F) up to +150°C (+302°F) subject to external/internal corrosion, leaks (dedicated procedure for live repair), dents and mechanical damages. The system restores the pipe integrity and prevents from further deterioration. This composite sleeve is made of 400 g/m² Kevlar® tape and highly-reinforced ceramic epoxy resin.

USES

- Reinforce pipe suffering from:

- internal and external corrosion

- pinhole, leakage, crack

- mechanical damage, dent

- severe abrasion, erosion

- sabotage …

- Restore pipe integrity

APPLICATIONS

- Onshore and offshore (topside)

- All pipe geometries including welds, elbows and tees

- All pipe sizes (no limitation)

- High pressure pipeline

- Pipe operating from -50°C up to +150°C

- Pipe transporting most common fluid and gas

BENEFITS

- Online repair (no shutdown required except in case of leakage)

- No loss of production

- Non-conductive repair

- No hot work

- Long-term performance (up to 20-year lifetime)

| Use | PIPE REPAIR & REINFORCEMENT |

| Pipe diameter | No limitation |

| Pipe temperature | 50°C / +150°C (-58°F / +302°F) |

| Fiber | Kevlar® |

| Resin | R3X55, R3X95, R3X110, R3X130, R3X70+, R3X150+ The most suitable resin will be selected according to the defect, the application and the temperature |

PREMIUM INSTALLATION BY TRAINED AND CERTIFIED APPLICATORS ONLY

Complementary product

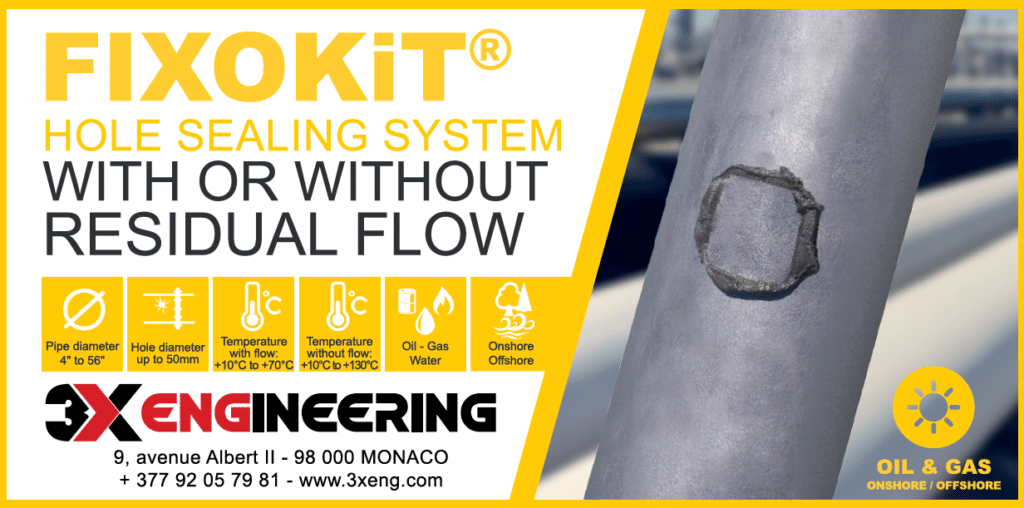

FIXOKiT® DESCRIPTION

FIXOKiT® is a hole and crack sealing system with or without residual flow. This unique and revolutionary concept, makes possible to plug through-wall defects. The installation can be carried out with the presence of residual flow.

FIXOKiT® technology adapts to different geometries (tee, elbow, straight line, oval pipe) and environments (Onshore/Offshore). This product can be used for various liquid fluids (oil, water, etc.) and gases. This is effective for most hole configurations, up to 50mm diameter.

The system can be installed on irregularities such as welds or corrosion cankers, making it the best system for repairing through-wall defects before composite wrapping designed as per ISO 24.817 and ASME PCC-2.