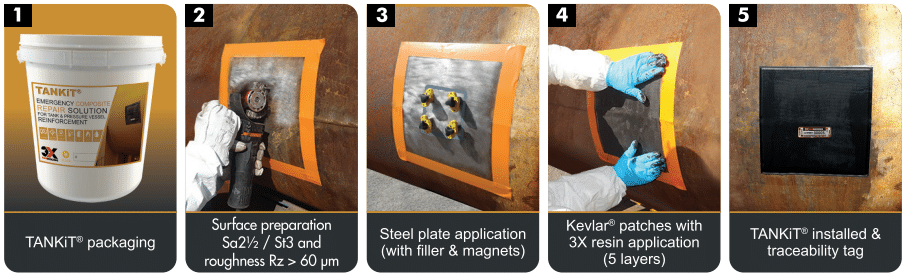

TANKiT®

TANKiT® is an emergency and temporary reinforcement solution designed to reinforce tanks and pressure vessels, restore original asset integrity and prevent further deterioration.

TANKiT® is a pre-engineered composite solution made of five Kevlar® patches impregnated with 3X specific resin. It can be applied without shutdown, unless active leakage.

This product is ready to use and does not require calculations. It can be used in specific conditions (up to 100mm defect size and maximum temperature +70°C).

USES

- Repair external/internal corrosion

- Repair through-wall defects up to 100mm

- Stop the corrosion (if external defect)

APPLICATIONS

- Onshore and offshore installations

- Various tank designs and up to 20m tank diameter

- Temperature up to +70°C (+158°F)

- Compatible with most common fluid and gas

BENEFITS

- No engineering, no calculations (ready-to-use)

- Online repair (no loss of production)

- Cold welding system, no heating or post-curing required

- Versatile product with a large range of applications (storage and GRP tanks, pressure vessels, separators, columns)

- Cost effective and easy to store

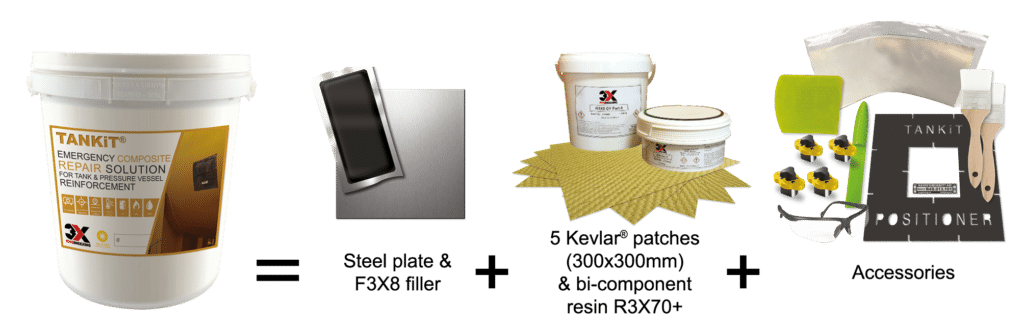

TANKiT® Components

1 TANKiT® = 1 repair

TANKiT® is a pre-engineered product sold in complete kit

| Use | TANK & PRESSURE VESSEL REINFORCEMENT – ONSHORE & OFFSHORE |

| Service temperature | -50°C / +70°C (-58°F / +158°F) |

| Application temperature | +10°C / +70°C (+50°F / +580°F) |

| Maximum tank diameter | Up to 20m |

| Maximum hole size | Up to 100mm |

| Maximum pressure | Depends on tank and defect diameter – See charts below (TANKiT® capacities) |