STOPKiT® VESSEL

Considered as an emergency repair, STOPKiT® VESSEL is a stop leak solution for pressure vessel and tank. It is the most efficient repair system applicable under pressure. This unique and revolutionary concept, patented by 3X ENGINEERING (3X), allows to fix high pressure leaks by tightening. Installation can be done without shutting down the line pressure.

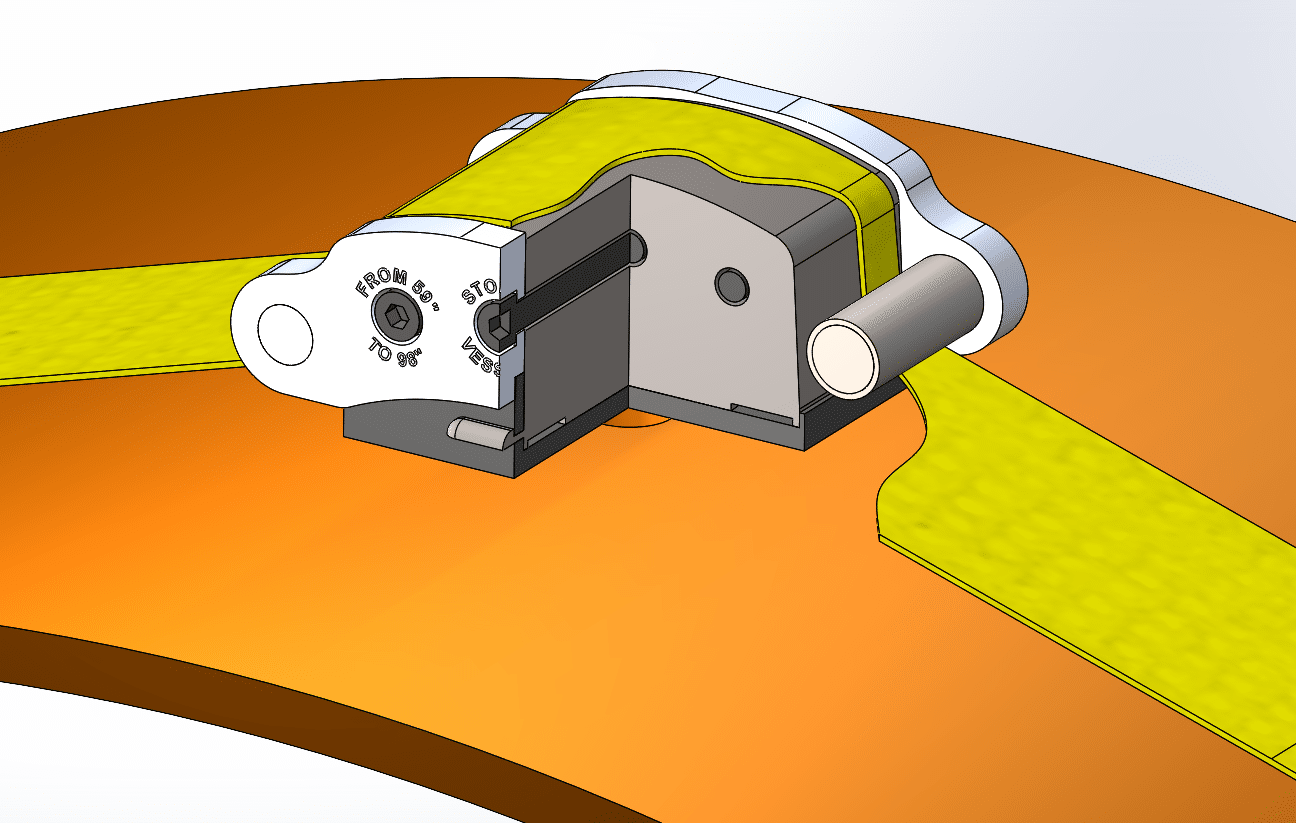

The tank/ pressure vessel surface must be without sharp edges, but the system can be applied on irregularity like welding wire or corrosion cankers, so it’s the best system to repair damaged and leaking tank/ pressure vessel.

This product has a large range of performance: it can stop a leak up to 30 bars on pressure vessels and tanks operating up to +80°C, from 1.5m to 3.5m diameters in onshore and offshore environments.

USES

- Emergency and temporary repair for leaking tank / pressure vessel

APPLICATIONS

- Onshore / Offshore

- Suitable on vertical / horizontal tank, pressure vessel

- Compatible with most common fluids and gas

- Diameter from 1.5m to 3.5 m (58’’ to 138’’)

- Temperature from –20°C to +80°C (-4°F to + 176°F)

BENEFITS

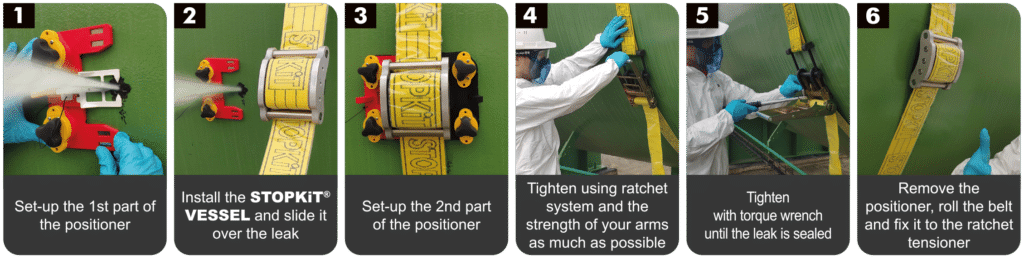

- Installation in less than 10 minutes (2 persons)

- No additional load on pipe (light product)

- Online sealing (no shutdown required)

- Ready-to-use and easy to store

- Reusable

- Shelf-life: 5 years

STOPKiT® VESSEL Concept

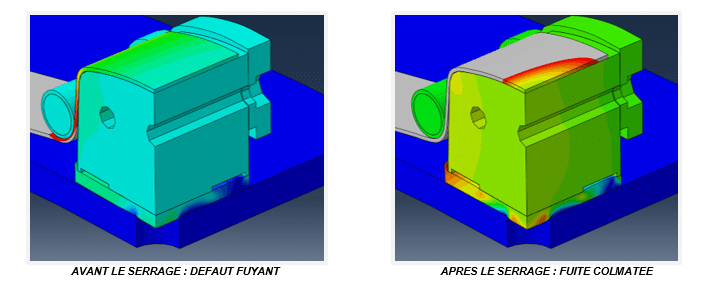

STOPKiT® VESSEL FEA study

STOPKiT® VESSEL COMPOSITION

- 1 belt + tightening system (ratchet strap and screws)

- 1 rubber Patch 100mmx100mm

- 1 torque wrench

- 2 positioners and 1 centerer

- 5 additional patches

- 1 White marker

- 6 magnets and tightening system for vertical tank (strip + magnets)

- 1 protective canvas large dimension (for the belt + tightening system)

- Installation procedure

Depending on tank diameter, the length of belt is subject to change. Do not modify the composition of the STOPKiT® VESSEL for quality purpose. Do not try to adapt a STOPKiT® VESSEL on another tank / pressure vessel diameter than mentioned on the packaging.

STOPKiT® VESSEL versions can be used in most environments: Onshore and Offshore. Because the environment is more aggressive in offshore conditions, the composition of the belt and the tightening system is slightly different to make it more resistant.

TECHNICAL SPECIFICATIONS FOR STOPKiT® VESSEL ONSHORE (2.5m & 3.5m)

STOPKiT® VESSEL ONSHORE version is dedicated for onshore environment such as refinery or inland tank.

The color of the belt is yellow.

TECHNICAL SPECIFICATIONS FOR STOPKiT® VESSEL OFFSHORE (2.5m & 3.5m)

STOPKiT® VESSEL OFFSHORE version is dedicated for offshore environment such as platform in harsh environment.

The belt of this STOPKiT® VESSEL is not only lighter and more flexible but is also very resistant to water/sea water. It will improve the long-term product efficiency. The color of the belt is red.

| DENOMINATION | STOPKiT® VESSEL 2.5 | STOPKiT® VESSEL 3.5 |

| USE | ONSHORE ENVIRONMENT – EMERGENCY REPAIR | |

| TANK DIAMETER | From 1.5m to 2.5m (58’’ to 98’)’ | From 2.5m to 3.5m (99’’ to 138’’) |

| MIN. TEMPERATURE | -20°C / -4°F | |

| MAX. TEMPERATURE | +80°C / +176°F | |

| PATCH SIZE | 100mm x 100mm | |

| MAXIMUM DEFECT SIZE | Ø≤ 40mm | |

| MAXIMUM PRESSURE | 30 bars / 435 psi | |

| DENOMINATION | STOPKiT® VESSEL 2.5 | STOPKiT® VESSEL 3.5 |

| USE | OFFSHORE ENVIRONMENT – EMERGENCY REPAIR | |

| TANK DIAMETER | From 1.5m to 2.5m (58’’ to 98’)’ | From 2.5m to 3.5m (99’’ to 138’’) |

| MIN. TEMPERATURE | -20°C / -4°F | |

| MAX. TEMPERATURE | +80°C / +176°F | |

| PATCH SIZE | 100mm x 100mm | |

| MAXIMUM DEFECT SIZE | Ø≤ 40mm | |

| MAXIMUM PRESSURE | 30 bars / 435 psi | |