HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | Dent defect in subsea environment |

| DETAILS | 24” OD – operating temp. 30°C – max. op. pressure 500 psi |

| LOCATION | Cartagena, COLOMBIA |

| 3X PRODUCT | REINFORCEKiT 4D Subsea (R4D-S) |

OVERVIEW

The objective of the repair performed by 3X ENGINEERING and its local distributor CPS was to reinforce a damaged subsea pipe section over 1.6 meter length, due to dent defect situated at 4 meter depth (7.4 % dented depth).

SCOPE OF WORK

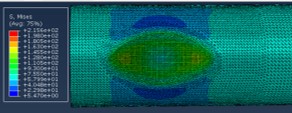

After Finite Elements Analysis (FEA), 10 composite layers of REINFORCEKiT 4D SUBSEA (R4D-S) product have been determined to perform the reinforcement.

Underwater, several preliminary operations (surface cleaning to get a suitable free span, removal of concrete and existing coating, marking of the surface to be wrapped) have been performed before the essential step of surface preparation (sandblasting) to get a good surface roughness (60-micron surface profile).

3X wrapping reinforcement has been performed following several stages :

1/ Primer (P3X32) application on the defect, using a dispensing gun, to provide a good adhesion of the composite materials.

2/ Two rigid composite plates recovered with F3XSS filler positioned over the dent and strongly fixed with ratchet belts during curing time of 2.5 hours.

3/ Second P3X32 application performed on the whole pipe surface to be repaired before wrapping.

4/ Kevlar® tape pre-impregnated with R3X1050-S resin (using special 3X device called BOBIPREG) wrapped around the pipe. Ten layers were necessary to cover the dent (i.e. about 5 passes of 50% overlap).

Finally, a neoprene soft cover has been applied to protect the repair from shells and other sea elements.

RESULTS

After several subsea repairs conducted recently in Viet-Nam, 3X ENGINEERING confirms its know-how in pipeline maintenance in underwater environment. A special thanks to client representatives and CPS team for their precious help to complete this project successfully within one day and in the best conditions.