HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | Leak & 3 external defects in subsea environment |

| DETAILS | 48” OD – max. operating temp. 25°C – calculated pressure 259 psi |

| LOCATION | Middle East |

| 3X PRODUCT | REINFORCEKiT 4D Subsea (R4D-S) |

OVERVIEW

The objective of the repairs performed by 3X ENGINEERING and its local distributor ASSET PROTECTION CONTRACTING was to reinforce a subsea pipe damaged by 4 defects: 1 leak and 3 external defects situated at 6-meter depth.

SCOPE OF WORK

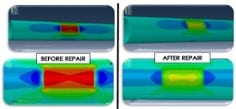

According to ISO 24.817 and 3X repair calculations, 30 composite layers of REINFORCEKiT 4D SUBSEA (R4D-S) product have been determined to repair the leak and 4 layers for each corroded defects.

Underwater, several preliminary operations have been performed prior to surface preparation (gritblasting) to get a good surface roughness (60-micron surface profile).

3X wrapping reinforcements have been performed following several stages:

1/ Primer (P3X32) application on the whole defect surface to provide a good adhesion of the composite materials.

2/ One composite plate coated with F3XSS filler positioned over the hole and strongly fixed with ratchet belts during curing time of 24 hours (only for leak repair).

3/ P3X32 applied on the whole pipe surface before wrapping.

4/ Kevlar® tape pre-impregnated with R3X1050-S resin (using special 3X BOBIPREG device) wrapped around the pipe. Thirty layers were necessary to seal the leak (i.e. about 15 passes of 50% overlap) and 4 layers for the 3 following defects.

RESULTS

After several repairs conducted underwater around the world, 3X ENGINEERING confirms its efficiency and capabilities in subsea pipeline maintenance. This job was a great challenge because of the large pipe diameter and the number of defects situated on 4 different locations for a total repair length of 21m. A special thanks to client representative and ZAMIL MERDAID company, which provided very competent divers and help us and our local distributor to deliver the repair successfully and on time.