HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | External corrosion – 4 defects |

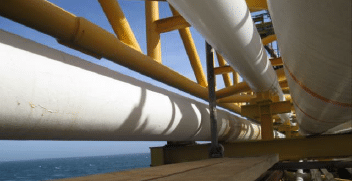

| DETAILS | PIPE DETAILS: 10” and 12” – Oil lines – design temperature 70°C - design pressure 40 and 200 bar |

| LOCATION | THE NETHERLANDS – Platform (Offshore on air) |

| 3X PRODUCT | REINFORCEKiT® 4D |

OVERVIEW

The objective of the repair, performed by 3X ENGINEERING (3X), was to repair and reinforce 4 external corrosion defects on 2 straight lines (2 defects situated on the 10” line and 2 defects on the 12” line). The pipes are located on the top of the bridge of the platform.

SCOPE OF WORK

Each repair is designed specifically according to the pipe characteristics, the operating conditions and the size of the defect. According to ASME PCC-2 standard and 3X repair calculations, 4 layers of REINFORCEKiT® 4D HT+, specifically dedicated to high temperature, were determined to repair each of the 4 defects.

Because of the complex pipes situation, the client provided scaffoldings to perform the repair.

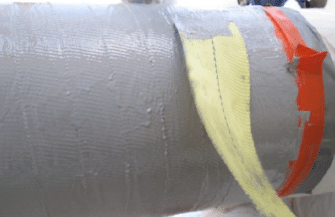

Before starting the composite reinforcement, 3X technicians first recognized and delimited the repair areas with adhesive tape. Surface preparation was completed with grit blasting to get a good surface roughness (between 60 and 100µm) and ensure the bonding between the steel pipes and the composite. The surface was then cleaned using acetone and hygrometric conditions were checked before wrapping procedure.

The composite repair for each defect was performed as follows:

1. F3X8 filler application on each defect to give back the initial shape to the pipes.

2. Wrapping process covering the delimited areas was completed using Kevlar® tape impregnated with R3XHT+ resin (4 layers for each defect but with a specific repair length in accordance to defect characteristics 260mm repair length for both 10” line defects, 457mm and 1060mm for the defects on 12” line).

3. Reference plate for traceability purpose was positioned on each repair.

For each repair, samples of filler F3X8 and resin R3XHT+ were taken during installation for quality control. After 3X operation, anti-UV coating was applied by the client to protect the repair.

RESULTS

The lines suffering from external corrosion were successfully repaired using our REINFORCEKiT® 4D HT+. Hardness measurements were performed and concluded the success of the repair. The design life for this composite reinforcement is 10 years.