HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

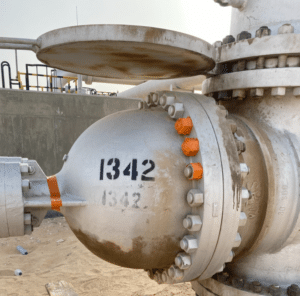

| DEFECT TYPE | Internal corrosion on 3 valves |

| DETAILS | Onshore, Oil, design pressure from 105 to 180 psi, design temp. 76.7°C |

| LOCATION | Kingdom of Saudi Arabia |

| 3X PRODUCT | REINFORCEKiT® 4D |

OVERVIEW

The objective of the repair, carried out by 3X ENGINEERING (3X) and its local distributor WISKOTS was to reinforce 3 valves with ball geometry suffering from internal corrosion. To restore valve integrity and prevent further deterioration, it was decided to repair the defected areas using REINFORCEKiT® 4D.

SCOPE OF WORK

According to ASME PCC-2 standard and 3X calculations, it was decided to apply REINFORCEKiT® 4D using R3X150+ resin (specifically dedicated to internal and external corrosion at high temperature). From 6 to 8 layers of composite were determined to reinforce the valves.

Surface preparation was completed with gritblasting to get a good surface cleanliness roughness (superior to 60µm Rz) and ensure a good bonding between the steel and the composite. Hygrometric conditions were checked and approved and the prepared areas were cleaned with acetone.

The composite repairs were then completed following below stages (application procedure is the same for the 3 valves to be reinforced).

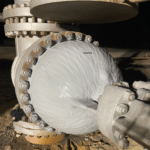

1/ F3XCOMB filler application on the defected areas to avoid sharp angles and reshape the valve before reinforcement.

2/ F3XS1 filler application to impregnate the surface and ensure good wetting and perfect impregnation of Kevlar® tape on the corroded areas.

3/ Composite covering using 300mm width Kevlar® tape impregnated with F3XS1 filler (1 layer) on internal corrosion areas.

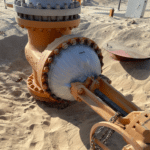

4/ Composite reinforcement using 100mm width Kevlar® tape impregnated with R3X150+ resin (for high temperature). The overlap is made by “L” patches on the complete circumference of the valves (depending on the valve and the level of corrosion, between 6 and 8 layers were applied).

5/ Finishing stage with id plate installation for traceability.

RESULTS

Hardness measurements validated the good curing of the applied products and concluded the good completion of the valve reinforcements.

The design life for these reinforcements is 20 years.

This job was quite complicated because of the specific valve geometry but was perfectly performed and will enable the sytem to operate efficiently and safely.