HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | subsea dent |

| DETAILS | 16” gas line – max. op. temp. 45°C – calculated pressure 93 bars |

| LOCATION | VIETNAM |

| 3X PRODUCT | REINFORCEKiT® 4D Subsea (R4D-S) |

OVERVIEW

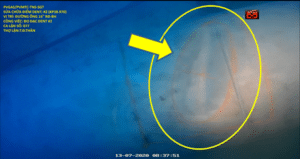

The objective of the repair, performed by 3X ENGINEERING (3X) local distributor PETROENERTECH, was to reinforce a 16” subsea pipe with dent (about 49.4-meter depth).

SCOPE OF WORK

According to ASME PCC-2 and 3X repair calculations, 41 layers of REINFORCEKiT® 4D SUBSEA have been determined to reinforce the damaged pipe section (dent size 280x260x35mm – 5.5% metal loss – 7.9% dented depth) with a 20-year lifetime design.

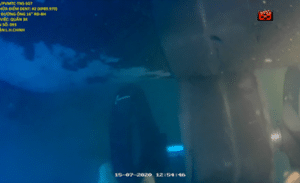

Underwater, preliminary operations (defected area identification, sand, rock and concrete removing etc …) were performed prior to surface preparation by sandblasting to get a good surface profile (superior to 60µm).

The composite repair was then performed following 4 main stages:

1. Composite plate covered with 3X subsea filler was applied over the defected area and maintained in position with 3 ratchet belts. After filler curing (3 hours), the belts were removed.

2. 3X subsea primer application over the dented area (previously delimited) to ensure a good bonding between the steel pipe and R4D-S composite wrapping. Hygrometric conditions were then checked before beginning the next step.

3. Kevlar® tape impregnated with R3X1050S resin and wrapped around the pipe. The tape impregnation was performed using BOBiPREG (3X specific machine allowing a quick and regular impregnation resin/fiber). To make continuity between 2 rolls of tape, metallic plates specifically designed by 3X for subsea operations were used. Forty-one layers were necessary to repair the defect for a total of 1.6m repair length.

4. Reference plate was positioned over the repair for traceability purpose. Thickness measurements were performed before installing a protective cover to preserve the line from marine aggressions.

Finally, hardness measurements were performed to validate the repair.

RESULTS

This subsea reinforcement was successfully performed using REINFORCEKiT® 4D SUBSEA product. Despite COVID-19 pandemic, this project was effectively conducted by PETROENERTECH, under the supervision of 3X Specialist by videoconference throughout the repair. This demonstrates the adaptability of 3X and its distributors facing the current health crisis.