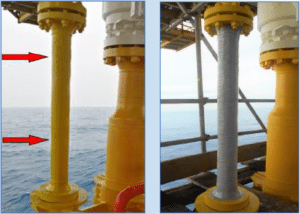

HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | External corrosion – 6 defects |

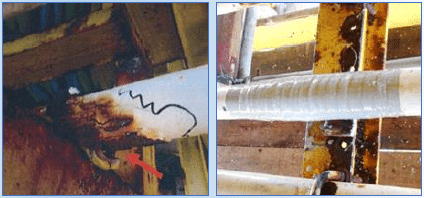

| DETAILS | Pipe details: 2” & 6” straight line, elbow, pipe on support and flange – hydrocarbon gas – operating temperature 80°C - operating pressure <12 bar |

| LOCATION | MALAYSIA – Puteri Platform |

| 3X PRODUCT | REINFORCEKiT® 4D |

OVERVIEW

The objective of the repair, performed by 3X ENGINEERING (3X) local distributor IN-SITU, was to reinforce 6 areas suffering from existing external corrosion and prevent from any potential internal corrosion.

SCOPE OF WORK

Calculations using 3X software were performed to define the minimum thickness and length necessary to give back the full integrity of the pipe, (according to the design pressure and temperature).

Following client’s request, it was decided to design the repair according to ISO 24.817. In these conditions, 3X advised to apply a minimum of 2 layers of REINFORCEKiT® 4D HT+ (specifically dedicated to high temperature) to reinforce the straight line, elbow, pipe on support and flange suffering from external corrosion.

IN-SITU specialists applied the composite online.

Before starting the 6 reinforcements, surface preparation was completed with grit blasting to get a good surface roughness and ensure the bonding between the steel pipe and the composite. Surface profile evaluation was performed to confirm the roughness was superior to 60µm. The surface was then cleaned using acetone and hygrometric conditions were checked before wrapping procedure (steps described below – for each reinforcement).

1. F3X8 filler was applied on the pipe.

2. Wrapping process covering the delimited areas was completed using Kevlar® tape impregnated with R3XHT+ resin (2 layers for each defect from 188mm up to 1085mm repair length).

3. Reference plate was installed on each repair for traceability purpose.

For each repair, samples of filler and resin were taken during application for quality control.

RESULTS

The 6 areas were successfully repaired using our REINFORCEKiT® 4D HT+. The challenge of these reinforcements was to repair online several geometries at high temperature.