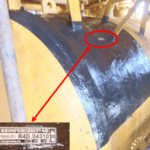

EMERGENCY COMPOSITE REPAIR SOLUTION FOR TANK AND PRESSURE VESSEL REINFORCEMENT

| DEFECT TYPE | External corrosion |

| DETAILS | TANK DETAILS: Reboiler - 64’’ OD - max. operating temp. 130°C - installation temp. 80°C - calculated pressure 20 barg – design lifetime: 20 years |

| LOCATION | VIET-NAM - FPSO |

| 3X PRODUCT | REINFORCEKiT® PATCH |

OVERVIEW

The objective of the repair performed by 3X ENGINEERING (3X) and its local distributor PETROENERTECH was to reinforce a reboiler located on FPSO suffering from external corrosion.

SCOPE OF WORK

After analysis of the corrosion extent, calculations according to ISO 24.817 were performed, concluding that 4 layers were needed to reinforce the reboiler. Because of the specific reboiler design, it was decided to use REINFORCEKiT® PATCH product, specially designed for tank & vessel repair i.e. 4 Kevlar®patches size 1032x1032mm for this case.

Surface preparation was completed, using Bristle Blaster machine, to remove coating and get a good surface roughness (between 60 µm and 100 µm anchor profile) to ensure a good bonding between the steel and the composite.

Before composite patching, dew point, moisture and surface temperature were checked and the surface was cleaned and degreased.

Composite repair was performed as per the following steps:

– F3XS1 filler was applied on the patch area (previously delimited) to fill metal loss and reshape the tank side.

– The surface was then covered with 3X specific epoxy resin (R3X1660) to ensure good wetting and impregnation of the Kevlar® tape.

– First Kevlar® patch was applied on the wet surface using paintbrush and making sure to remove all air bubbles. The Kevlar® patch was then impregnated with R3X1660 resin in order to create the wet surface for the next patch. This step was repeated until the good number of layers was reached (4 layers/patches).

– Final layer of epoxy resin was applied over the repair for protection.

Identification plate was positioned on the tank for traceability.

RESULTS

Thanks to the efficient collaboration between 3X and its local distributor the corroded area of the reboiler was successfully repaired. The reboiler integrity is now restored.