HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | Pipe subjected to compressive stress |

| DETAILS | 30” pipe – Operating temperature 45°C - Pressure 600 psi |

| LOCATION | COLOMBIA |

| 3X PRODUCT | REINFORCEKiT® 4D (R4D) |

OVERVIEW

The objective of the job, carried out in Colombia by CPSERVICES

(3X ENGINEERING (3X) distributor), was to reinforce and protect a 30″ pipe subjected to compressive stress in order to verify if the pipe integrity remains preserved once loads are applied.

SCOPE OF WORK

Each reinforcement is designed specifically according to the characteristics of the pipe, the operating conditions and the size of the defect. In accordance with ASME PCC-2 standard and 3X repair calculations, 4 layers of REINFORCEKiT® 4D-EC were determined to reinforce the pipe.

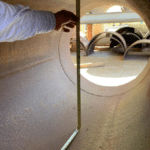

1/ Before the repair, qualified staff of CPSERVICES inspected and delimited the area to be reinforced.

2/ Surface preparation was carried out by an external contractor using manual-mechanical tools to obtain a good surface roughness (between 60 and 100 µm) and thus guarantee the bonding between the steel pipe and the composite.

3/ The surface was cleaned with ethanol and the hygrometric conditions were checked before wrapping process.

4/ Wrapping composite reinforcement covering the delimited area was completed using Kevlar® tape impregnated with R3X1060 resin (4 layers with a specific repair length according to the characteristics of the loads to which the 30″ pipe would be subjected).

5/ Once wrapping completed, the inner diameter was measured in order to detect any final deformation.

6/ Finally, two external loads (1.75 tons each one) were applied to check the resistance of the pipe.

RESULTS

The pipe reinforced with REINFORCEKiT® 4D was subjected to 3.5 tons of external loads without presenting any type of damage or deformation. The lifetime of this composite reinforcement is 20 years.