HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | Internal metal loss |

| DETAILS | 16” gas line – max. op. temp. 45°C – op. pressure 125 bars |

| LOCATION | Viet-Nam |

| 3X PRODUCT | REINFORCEKiT® 4D Subsea (R4D-S) |

OVERVIEW

The objective of the repair, performed by 3X ENGINEERING (3X) and its local distributor PETROENERTECH, was to reinforce a 16” subsea pipe suffering from internal corrosion at 45-meter depth.

SCOPE OF WORK

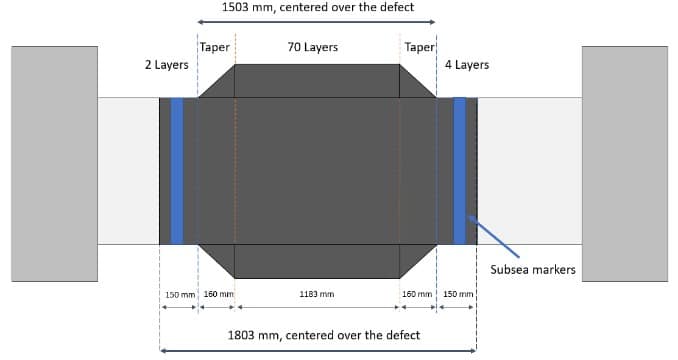

According to ASME PCC-2 and 3X repair calculations, 70 layers of R4D-S have been determined to repair the defect.

Underwater, preliminary operations were performed prior to surface preparation by sandblasting to get a good surface profile (superior to 60µm).

The repair was then performed following 5 main stages:

1. Preparation of the composite plate recovered with F3XSS filler and application over the defect using ratchet belts for tightening (after 2 hours of curing, the belts were removed).

2. P3X32 primer application on the whole area to be repaired before wrapping to ensure a good bonding between the steel pipe and the composite.

3. Kevlar® tape impregnated with R3X1050S resin and wrapped around the pipe. The tape impregnation is performed using BOBIPREG (3X specific machine allowing a quick and regular impregnation resin/fiber). Seventy layers were necessary to repair the defect (i.e. 35 passes of 50% overlap) for a total repair length of 1503mm.

4. Specific subsea markers installation on the composite (to avoid any contact with the pipe), on each side of the repair. For that reason, it was necessary to increase the length of the repair of 150mm each side to be able to install these markers.

5. At client’s request, 3X created and installed these subsea devices to localize easily the defect at pigging inspection.

Finalization of the repair with reference plate positioning for traceability purpose and protective cover application over the repair to protect the pipe from subsea aggressions.

RESULTS

The subsea reinforcement was successfully performed using REINFORCEKiT® 4D SUBSEA product. The good collaboration between 3X specialists, PETROENERTECH, PVMTC (diving company) and the client’s representatives is also the key to success of this job.