HIGH-PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT

| DEFECT TYPE | 178 joint sections suffering from internal damages |

| DETAILS | PIPES DETAILS: 2inch piping spools– Sour Water– design temp. 85°C – design pressure 30.5 barg |

| LOCATION | QATAR |

| 3X PRODUCT | REINFORCEKiT® 4D |

OVERVIEW

The objective of the repair, carried out by PEC team (Power Engineering Corp. / Alqodara Alhandaseya Co), 3X ENGINEERING (3X) local distributor was to reinforce piping spools areas suffering from internal damages.

SCOPE OF WORK

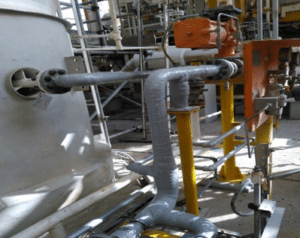

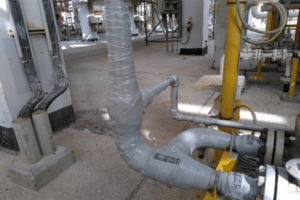

Calculations using 3X software and according to ISO 24.817:2017 were performed to define the design of the repair. PEC advised to apply 6 layers for straight line, 8 layers for bend, 8 layers for flange, 8 layers for reducer & 12 layers for tee sections with REINFORCEKiT® 4D (R4D).

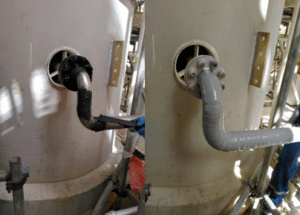

Surface preparation was completed by PEC team, using Bristle Blaster machine, in order to get a good surface roughness (superior to 60μm Rz) and ensure the bonding between the substrate and the composite system. Hygrometric conditions were checked and the surface was cleaned and degreased with acetone (steps described below – the procedure was the same for the second piping spool to be reinforced).

F3XS1 ceramic anti-abrasion filler were applied over the defected weld joint. A minimum of 3mm thickness of ceramic filler F3XS1 was applied over each joint section. Climatic conditions were checked before moving on composite wrapping.

Wrapping process to reinforce the defected area (previously covered with epoxy resin to ensure good wetting and impregnation of the tape) was completed using Kevlar® tape (i.e.: specific size tape for small pipe diameter) impregnated with 3X specific epoxy resin.

Last layer of epoxy resin was applied all over each repair and reference plate was installed for traceability purpose.

For each repair, samples of filler and resin were taken during application for quality control.

➔ 178 joint sections were successfully completed using R4D composite system in 4 weeks by 1 composite specialist and 4 applicators. This job represents over 35m repair length.

RESULTS

The 3 piping lines were successfully repaired using R4D composite solution (i.e.: 2-year repair lifetime). This project was quite complicated due to the total numbers of spools to be wrapped and the difficult accessibility to perform the repair but was completed on time as per the schedule required by the client. All the COVID-19 safety measures were correctly respected.